What is Remanufacturing?

REMANUFACTURE (VERB) | Pronunciation: / rɪˈmanjʊˈfaktʃə

- To return a used product to at least its original performance with a warranty that is equivalent to or better than that of the newly manufactured product.

- Involves dismantling the product, restoring and replacing components and testing the individual parts and whole product to ensure that it is within its origin design specifications.

- From a customer viewpoint, the remanufactured product can be considered the same as a new product.

- Subsequent warranty is generally at least equal to the new product.

- Performance after remanufacture is expected to be at least to the original performance specifications.

Remanufacturing is an important component of a resource efficient manufacturing industry. By keeping components and their embodied material in use for longer, significant energy use and emissions to air and water (e.g. CO2 and SO2) can be avoided. In addition to environmental benefits, remanufacturing provides opportunities for the creation of highly skilled jobs and economic growth.

Benefits of remanufacturing

Lower prices

Remanufactured products are typically 60-80% of the cost of a new product due to the cost savings made from the recovery of the materials and energy content of the product.

Availability

For products that are manufactured to order overseas, a remanufactured product may be available with a shorter lead time. Additionally, remanufacturing may allow the customer to continue to use equipment that is no longer be manufactured.

Purchasing flexibility

As remanufacturers have a real interest in knowing where their products are and recovering them they might offer their customers a range of services beyond the initial sale. Leasing, take-back, upgrading, supply-and-operate provide gains for both parties: Capital costs can be amortized, supplier relationships can improve and “whole life solutions” mean there are no disposal worries at end of life.

Reduced raw material consumption

As remanufacturing preserves much of the material in original product, less raw material is used than for manufacturing new products. This is particularly beneficial where the product contains critical raw materials – materials where there is a supply risk.

Reduced energy consumption

By limiting the amount of raw material extracted/recycled and the manufacturing of new components, remanufacturing typically uses less energy than manufacturing a new product.

Reduction in CO2 emissions

A reduction in energy consumption is usually accompanied by a reduction in CO2 emissions.

Reduction of material sent to landfill

Not all end-of-life products and/or their components are suitable for recycling but instead end up in landfill. Remanufacturing reduces this flow of material by keeping material in use for longer.

Local jobs

Remanufacturing activities usually take place close to market so, whilst a product may have originally been manufactured overseas, remanufacturing provides the opportunity for creating local jobs.

Higher profit margins

Remanufactured products often have higher profit margins than the original manufactured item.

Skilled jobs

Remanufacturing is a great breeding ground for problem solving skills, more rewarding than production line jobs, and often retaining traditional industrial skill bases.

New manufacturing techniques

Leading edge remanufacturers embrace state-of-the-art manufacturing processes – lean techniques, investment in people, material traceability – because they are key to business success.

Better customer relationships

Through trade-in schemes, remanufacturers can build a better relationship with their customers than those who rely on throw-away, one-off purchases.

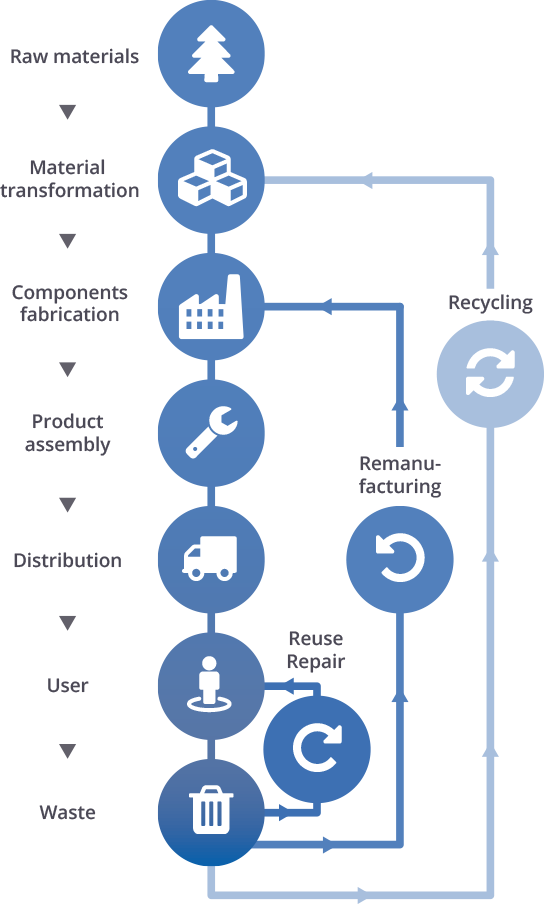

Product lifecyle process

European landscape

The ERN consortium partners have constructed an European wide market study on remanufacturing. The report provides an overview of the current and potential structure and size of the European remanufacturing industry.

[PDF] Market studyAdvanced materials

The project also studied the potential of remanufacturing to preserve so-called critical (or ‘advanced’) raw materials.

[PDF] Advanced materials ReportRecommendations

This report summarises the findings and recommendations of the project.

[PDF] Recommendations ReportRemanufacturing eLearning

Five free video sessions exploring remanufacturing policies, design and processes.

[VIDEO] eLearning